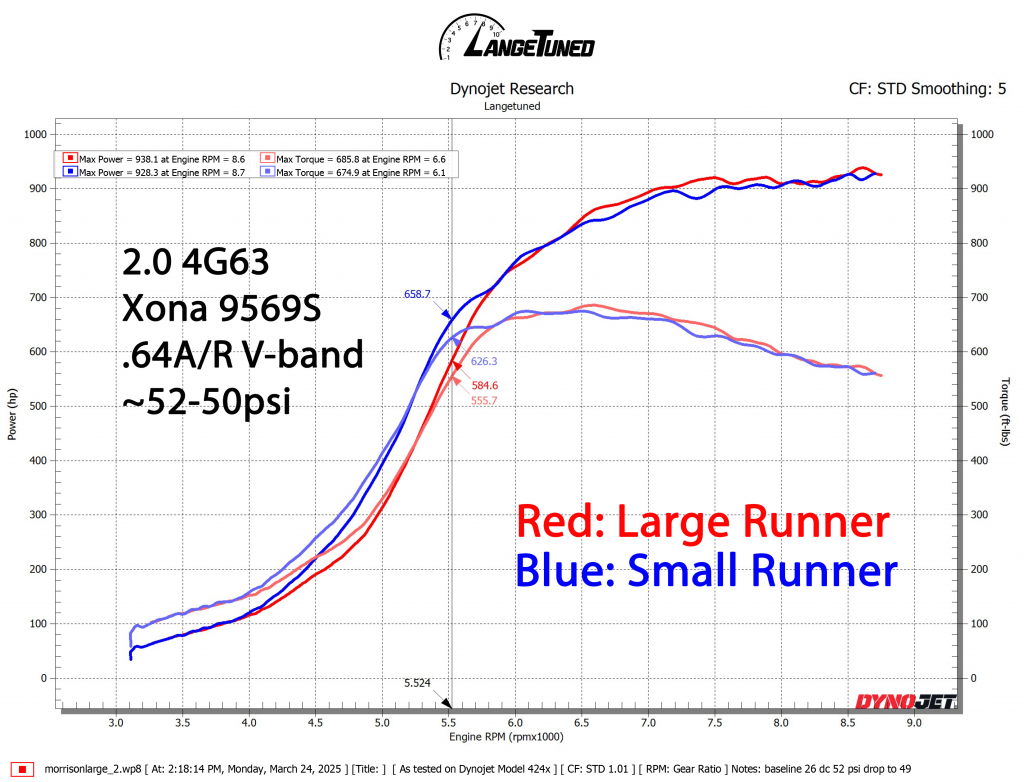

This test was between two of our DSM Xona V-band standard placement/bottom mount manifolds, with the runner/primary size being the only variable- identical placement, routing, and design with near equal lengths. The two runner sizes were sch10 1-1/2NPS for large runner (1.68″ ID or just over 1.75″ comparable tube size) and sch10 1-1/4NPS for small runner (1.42″ ID or a little over 1.5″ comparable tube size). It’s noteworthy that the small runner cross sectional area (CSA) transitions smaller than the factory exhaust port CSA- the large is very close to the same area after forming. Testing was performed at Langetuned with his Dynojet chassis dyno. All overlays done on the same day, with the manifold swapped while still strapped on the dyno.

McKenzie’s Setup:

– STD 2.0L 4G63 10.5:1 comp

– Xona Rotor 68mm 9569S turbo (.64 A/R Tial v-band, the UHF turbine wheel tends to flow like a larger A/R)

– Tuned on Haltech by himself (Langetuned)

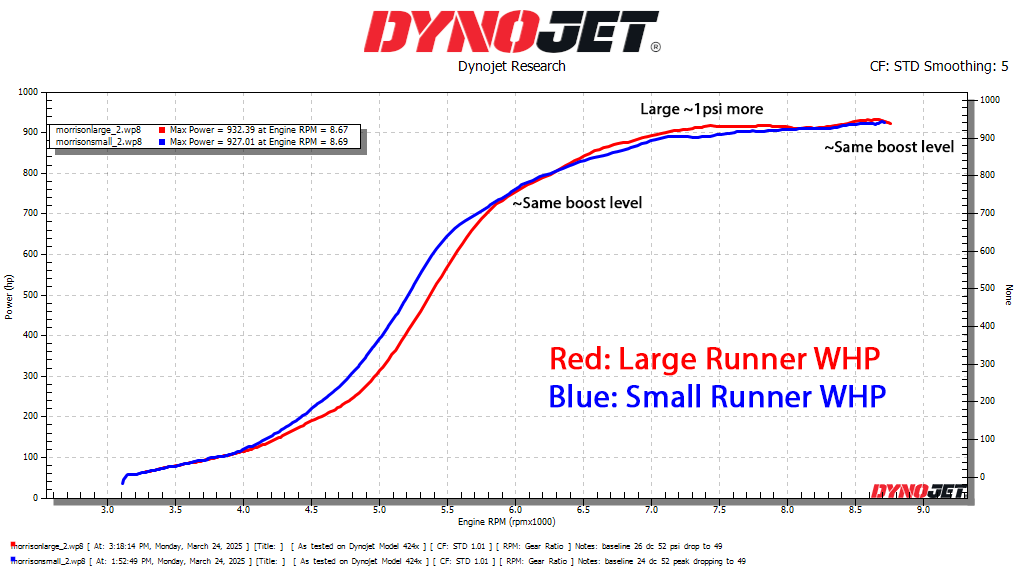

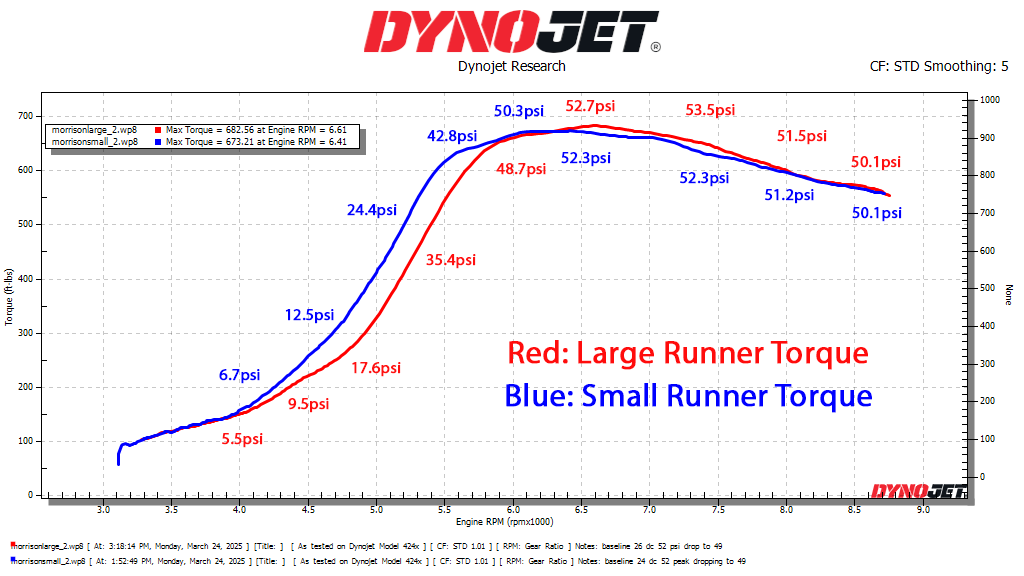

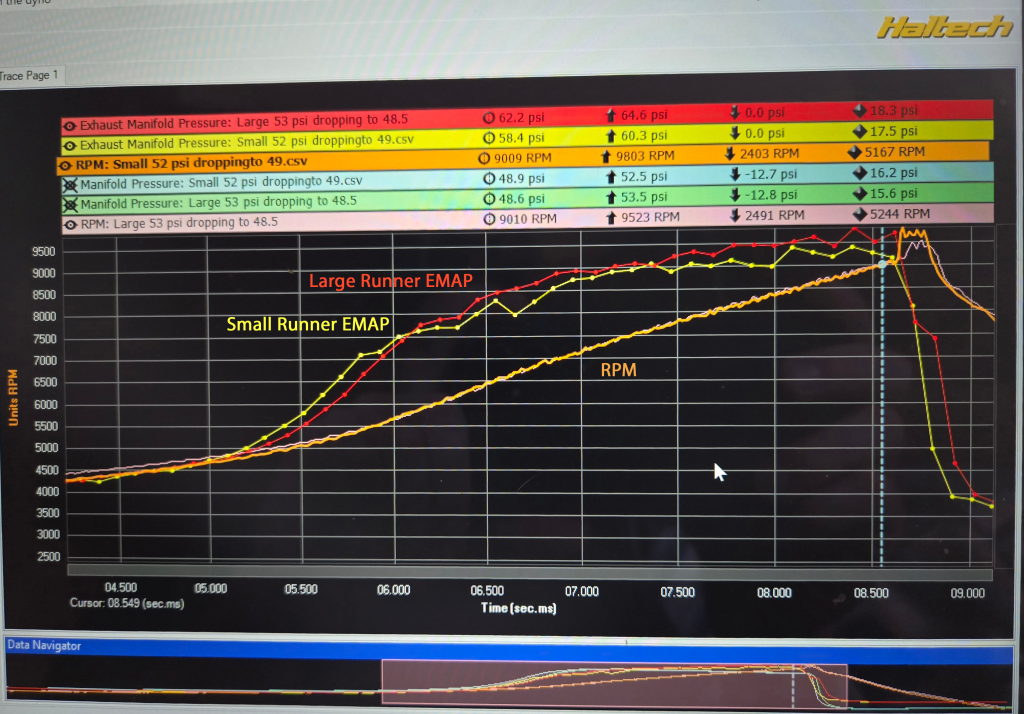

Shown are the high boost runs since they had the least variance in psi, hitting ~52/53psi and both falling to 50psi at peak power. Lower boost runs followed the same trend, but this is probably what most folks are interested in:

It was fairly expected for the smaller runner size to come into boost sooner, but we were looking for a power/rpm crossover point where it required more boost for the same power, nosed over, or just wasn’t happy in general.

Both manifolds ended up having nearly identical overall power and torque curve shapes, with the small runner consistently ramping in about 210-230rpm sooner and staying nearly on top of each other at high rpm.

The power differences mostly came down to boost variances. Taking that into account, the large runner seemed to have a slight edge in power per psi with this combination, which is opposite of the 62mm divided T4 test years ago (which were more pronounced). The small runner did end up with slightly higher VE/fueling requirements, which is often a good sign, but it didn’t translate to more power at the same boost that usually comes with higher VE (based off the wideband O2 readings). Prior street testing was splitting hairs to find a slight difference up top, and we didn’t expect the dyno to be this close too. Maybe 10-20hp more with the large in some pulls, but more often than not, it was just a small fraction more boost instead.

We were mostly interested in comparing torque at points where boost was identical, and if the variances were proportional with boost. Labelling the boost levels along the torque curve shows how closely they tied together.

The small required less wastegate duty cycle (24% vs 26%) for the same target psi and ramped boost in sooner. From a point where both were at 3800rpm and 5psi, the large runner took 3.33 seconds to hit 30psi, and the small runner took 2.75 seconds to hit 30psi.

Drive pressure/backpressure on each manifold read between 1.2 and 1.25:1 EMAP:MAP at 9000rpm, which is really good also considering the .64A/R at this power level, and seems to show how well the UHF turbines flow in a smaller than typical A/R in our application.

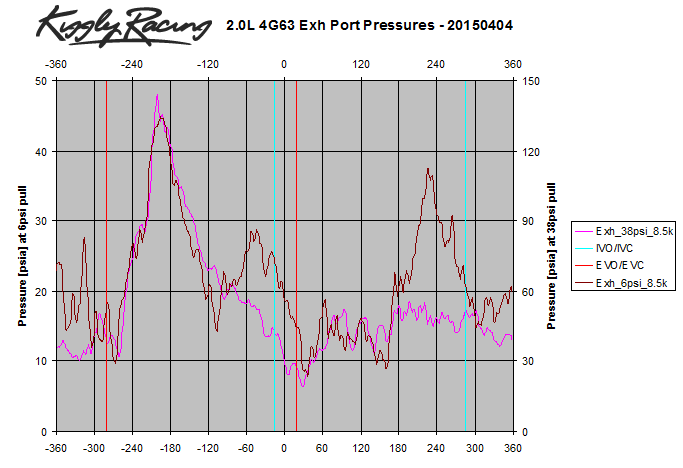

Surprisingly, the small runner drive pressure was reading consistently lower by a few psi. That could be an artifact of the reading itself (referenced off the EGR port), but bulk/average drive pressure comparison between manifolds doesn’t show the complete picture anyway- not in the same way it can with a turbo or exhaust system. Larger will “flow” more but we aren’t dealing with continuous flow, rather a cycling on-off-on-off with opportunities for flow in the wrong direction too. Especially near the end of the exhaust stroke and overlap that can have a direct impact on overall airflow through the engine.

Exhaust pressure trace diagram courtesy of Kiggly Racing (from their own, much more in-depth personal testing using pressure transducers etc.)

A manifold/design change will affect the how each cylinder sees the wildly oscillating pulses and waves in the exhaust stream before the turbo, and potentially shift the peaks and valleys up/down/over to benefit or hurt cylinder filling (VE), reversion, pumping loses, etc. All within the same average pressure reading. If the complex pressure trace is the music, the average is only the volume level.

These results won’t apply to every manifold or configuration sharing the same runner size of course. And a manifold can certainly end up choking the setup, although McKenzie didn’t see any sign of it with either.

There is no one-size-fits-all when it comes to runner diameter. Larger runners are often used in high power/rpm turbo setups for good reason, with certain applications/configurations making them more ideal, and smaller runners being more sensitive to certain manifold design/features. But if well implemented, smaller can sometimes exceed expectations.

There seemed to be some push and pull effects at this turbo size and power level, making each runner size look very similar besides spool up. This wasn’t the case with smaller/lower power levels, and is unlikely to hold true with larger turbo/higher power level combinations.

Another back-to-back test at lower power levels with a divided T4 Evo,

Large vs small 700whp 62mm test with a greater difference in power per psi

We’re just glad that even basic design changes can have noticeable and sometimes counterintuitive effects. Probably what makes turbo setups so interesting.

Finding out how/why is what we do this for.

——————————

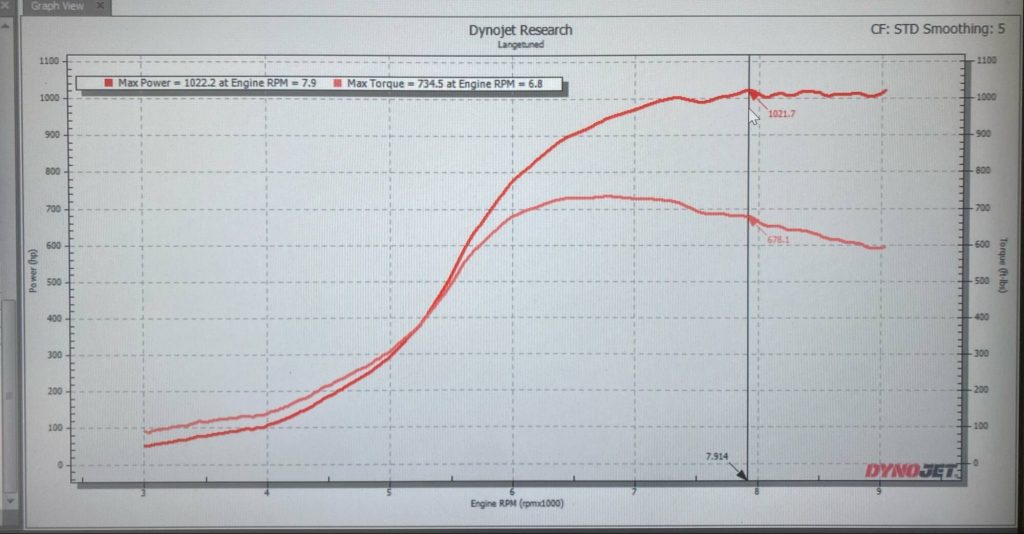

Attached is the small runner with a little more boost and ignition timing back in, just to see:

1022whp/734wtq and holding strong to 9000rpm, 55psi falling to 51psi

1.3:1 (EMAP:MAP) at 9200rpm on this pull

A huge thank you to McKenzie for making this all happen