Large vs. Small runner

We’ve always felt strongly about taking advantage of runner/primary sizing and matching it to the setup, which is nothing new for manifold/header building, but somewhat uncommon for most DSM and Evo turbo manifolds. Historically, “large” runner options have been by far the most common; and for good reason, as it feels somewhat awkward to step down in size from the cross sectional area (CSA) of the 4G63 exhaust port. This write up will seem very “small runner” focused, and it certainly is, as large runner manifolds are already well proven and will mainly serve as the benchmark.

The first manifold we made used small runners in 2010 and Ron Shearer had been experimenting with them since 2008, with him and David Buschur doing their own testing in 2010. Larger runners/primaries can overall flow more and will tend to be more favorable at high power and high rpm setups, while a smaller runner/primary will have a higher velocity and pulse strength, tending to be more responsive at lower rpm and offer an increased power/torque curve up to a certain point or setup- which can be hard to pinpoint where that crossover point will be and when one will shine over the other. We’ve had lots of direct and indirect data from others, and indirect data from tests of our own that we’ve based our knowledge on, but never an opportunity for a dedicated test with runner size being the only variable- until now.

Brandon’s setup was considered “on the fence” for our rule of thumb as far runner size since it was a 62mm turbo and 2.1L engine, but he also wanted the most response possible with the most area under the curve (which a divided T4 combination is already great for), even if that meant a little loss in peak power. This made his setup an ideal candidate for a large vs small runner test while his build was being done at Whalen Speed R&D, allowing him to make his manifold decision based on the dyno test results and allowing us to gather some fantastic data.

The main goals of this particular test were to:

- To get a direct comparison between the two runner sizes we use, with a dyno overlay to visually show if/when/where one shines over the other and by how much at different boost and power levels.

- Perhaps most importantly- to calibrate our own intuitions and thoughts behind our manifold suggestions and which runner size may be the best match with our clients setup/goals; based on power level, rpm range, turbo size/future upgrades, intended use, and their own personal preference on power delivery.

A big thank you goes out to Brandon for offering his Evo 9 to test run the power curves of each of our manifolds and John and the team at Whalen’s Speed R&D for making the test happen- putting in the extra time to swap manifolds, recalibrate AFR’s, boost curves, and document all of the data collected.

Check ‘em out on facebook: https://www.facebook.com/whalentuned/

or on their website: www.whalenspeed.com

Dyno Test Background and Methodology:

This test was between two of our Evo 8/9 Divided T4 standard placement/bottom mount manifolds, with the runner/primary size being the only variable- identical placement, routing, and design with near equal lengths. The two runner sizes were sch10 1-1/2NPS for large runner (1.68″ ID or just over 1.75″ comparable tube size) and sch10 1-1/4NPS for small runner (1.42″ ID or a little over 1.5″ comparable tube size). The turbo was a 62mm Borg Warner S362SX-E with 76mm turbine and .91A/R divided T4 turbine housing. Testing was performed at Whalen Speed R&D in Paw Paw, MI between March 4th and April 27th, 2020, using a Dynojet chassis dynomometer with the Large Runner Divided T4 installed first for baseline runs. Some early 3rd gear pulls resulted in wheel spin so John redid the runs in 4th gear and for the remainder of the test for consistency. After multiple baseline runs at different boost levels with the larger runner manifold, the team swapped to the small runner but unfortunately not on the same day and encountered some inevitable delays due to the state wide lock downs. Final comparison pulls were done at 30psi, 32.5psi, and 38psi between the two manifolds/runner sizes.

Some changes had to be made with John adjusting the wastegate duty cycle (WGDC%) and boost ramp rate between manifolds (more covered on that later) to control boost as well as changes in fueling to get AFR back in line from the different VE and airflow requirements between each manifold/runner size. Other variables, such as target AFR, ignition timing, MIVEC settings, etc were kept the same. Dyno room temperatures varied between 66 and 77 degrees F, and IAT at the start of each pull varied between 66 and 82 degrees F. All pulls were started steady-state at 2500rpm.

Design factors involved in the manifolds used:

~1.68″ runner ID for the Evo Large Runner Divided T4

~1.42″ runner ID for the Evo Small Runner Divided T4

Some things worth noting:

- We have our own method and process to gently form the transition from oval exhaust port to runner, particularly when the cross sectional area (CSA) of the runner is less than the CSA of the factory 4g63 exhaust port (in the case of the small runner manifold). We feel this is very important in attaining the results seen during this test, giving the small runner manifold a fair shot, and a large piece of what sets us apart. (More info: http://morrisonfabrications.com/tech/oval-port-flange-vs-transition-flange/)

- This test was comparing two of our own manifolds, not a test against a manifold that has any inherent compromises to begin with; such as tight radius bends, poor transitions, or a less than ideal collector. This comparison is just primary size- with both arguably being stout performers to begin with. It’s fairly established that our small runner manifolds are efficient in the 750whp range, but what the power curve looks like next to a large runner as they both approach that power level is less known and what this test is about.

- Setups with smaller turbos/less power will tend to prefer the small runner manifold more than this test, and setups with larger turbos/more power will tend to benefit from the large runner manifold more than this test. This test is meant to be a middle ground to find that crossover point in the power level/rpm level where one runner size starts to shine over the other.

- This test and results are specific to the setup being tested, but similar relative results are to be expected for all of our large or small runner manifolds (Evo, DSM, etc).

There will always be variables, however, such as turbo size and efficiency (both compressor and turbine), turbine housing A/R, open vs divided, operating rpm range, boost level, engine displacement, camshafts/valve events, etc.

Data Analysis:

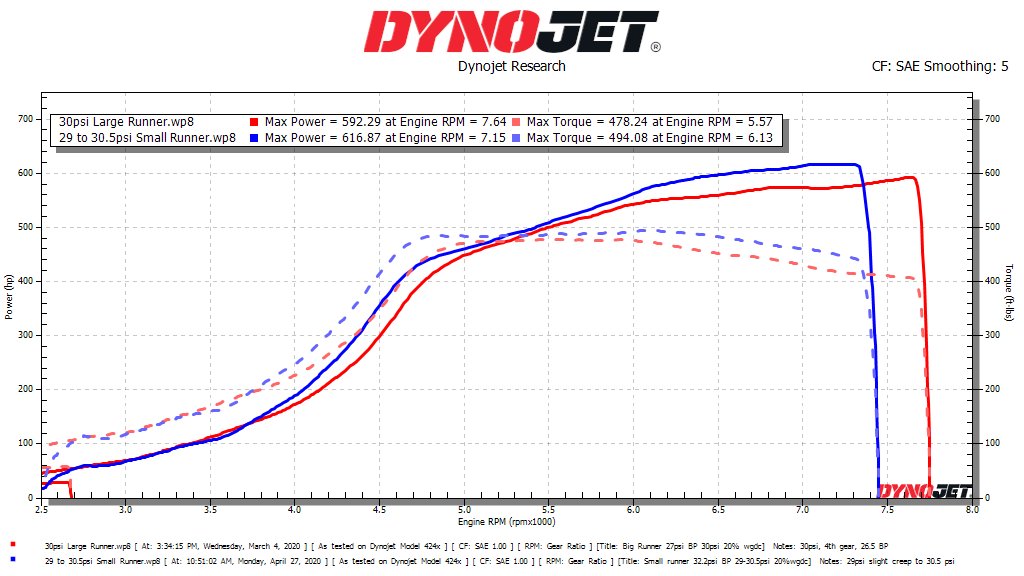

The MF large runner vs MF small runner overlays:

Large runner was a steady 30psi while small runner hit 29psi then rose to 30.5psi by the end .

Small runner picked up ~66wtq at 4500rpm during spool up and made ~40whp more at 7000rpm (with an unfair 0.5psi advantage at this point).

Peak numbers:

592whp/478tq Large runner @30psi boost, ~27psi peak drive pressure

617whp/494tq Small runner @30.5psi boost, ~29psi peak drive pressure

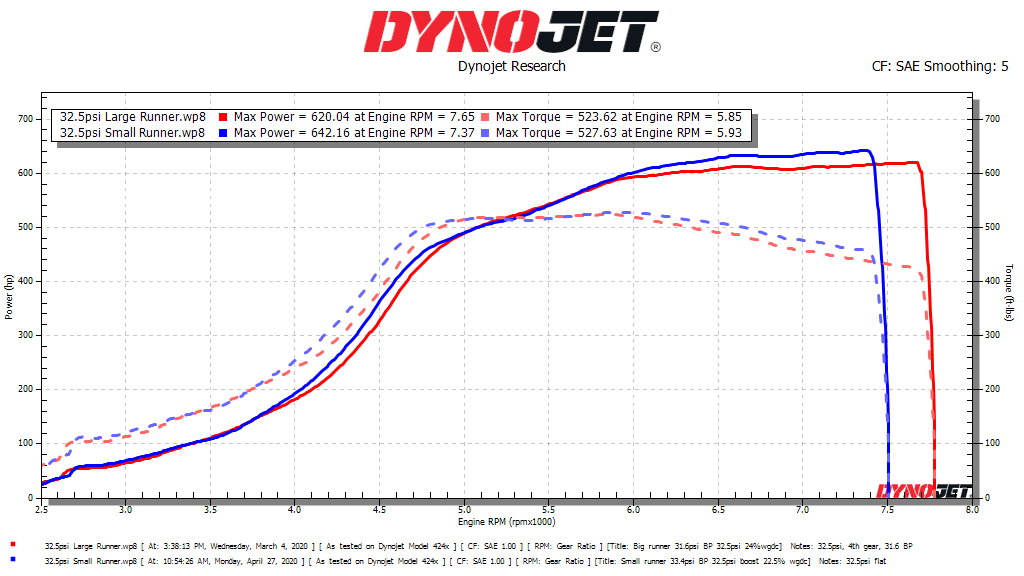

Both held a solid 32.5psi. Small Runner picked up ~40wtq at 4500rpm during spool up and ~25whp after 7000rpm. There is a point at ~5250 rpm where both curves dip (both go rich as the second fuel pump kicks in) and the large runner makes ~5whp/5wtq more.

Peak numbers:

620whp/524wtq Large runner @32.5psi, ~32.5psi peak drive pressure

642whp/528wtq Small runner @32.5psi, ~33psi peak drive pressure

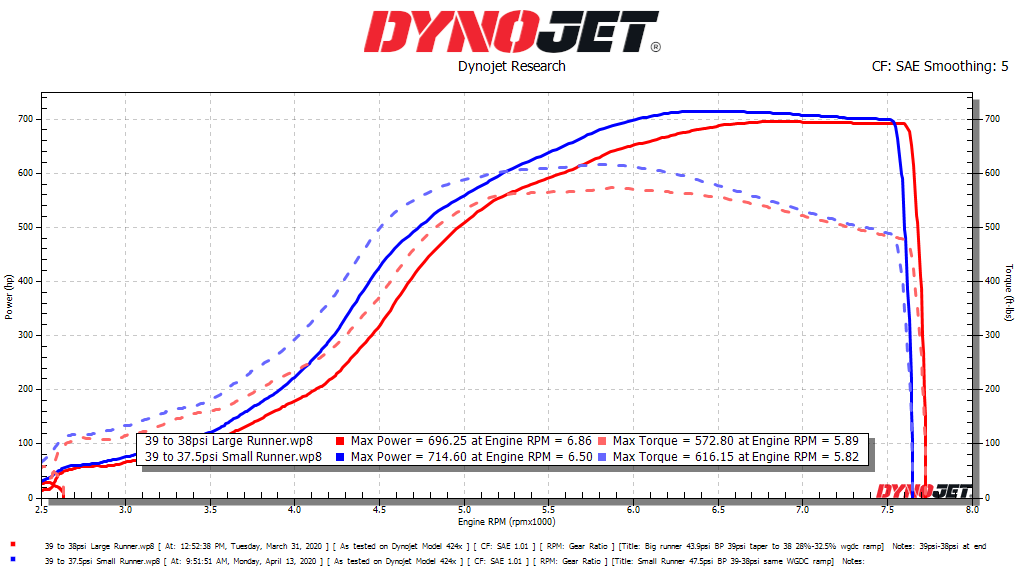

Both hit 39psi, the large runner fell to 38psi and small runner fell to 37.5psi by the end.

Small runner picked up ~120wtq at 4500rpm and maintains about 40wtq more until 6000rpm. The small runner still has a 5whp advantage at 7500rpm despite being down 0.5psi vs the large runner.

Something important to note is that this is the first (and only) small runner manifold pull where the boost ramp rate was the same between the large and small runner pulls. The later lower boost small runner pulls were done with a less aggressive boost ramp rate and WGDC% to soften how the small runner manifold comes into boost (due to the pulls being done in 4th gear on the dyno which can put extra wear and tear the drivetrain).

Peak numbers:

696whp/573wtq Large runner @38psi boost, ~43psi peak drive pressure

715whp/616wtq Small Runner @38psi boost, ~47psi peak drive pressure

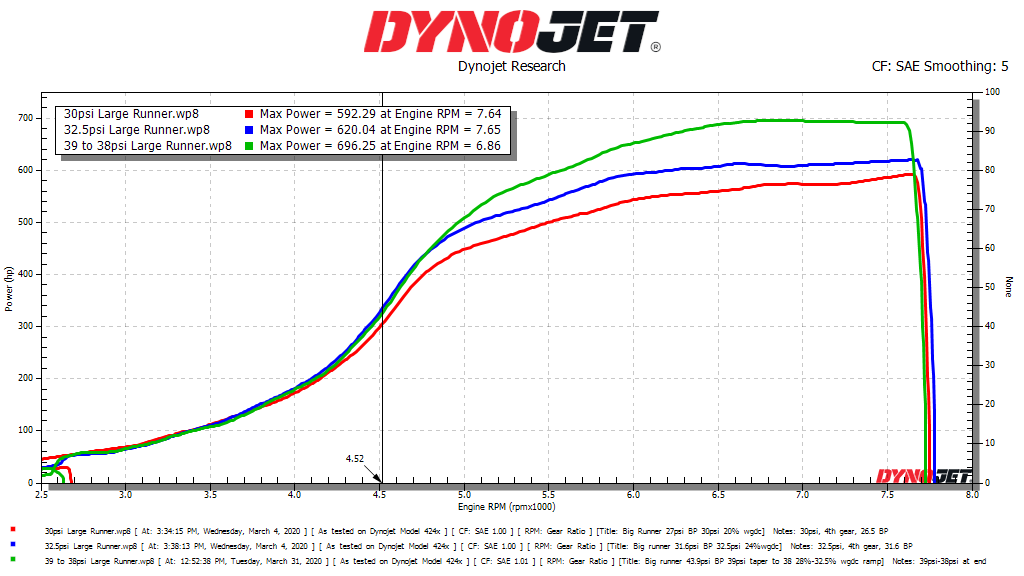

MF Large Runner manifold overlaid at each boost level:

Red 30psi, blue 32.5psi, and green 39 to 38psi.

All of these pulls had the same boost ramp rate, with the red (30psi) pull spooling slightly later- likely due to the wastegate opening a little sooner with less initial fixed WGDC%.

Each successive increase in boost tracks nicely, and the shape of the power curve starts to level off sooner on the higher boost pull, likely dictated by the 62mm turbo getting closer to its limit.

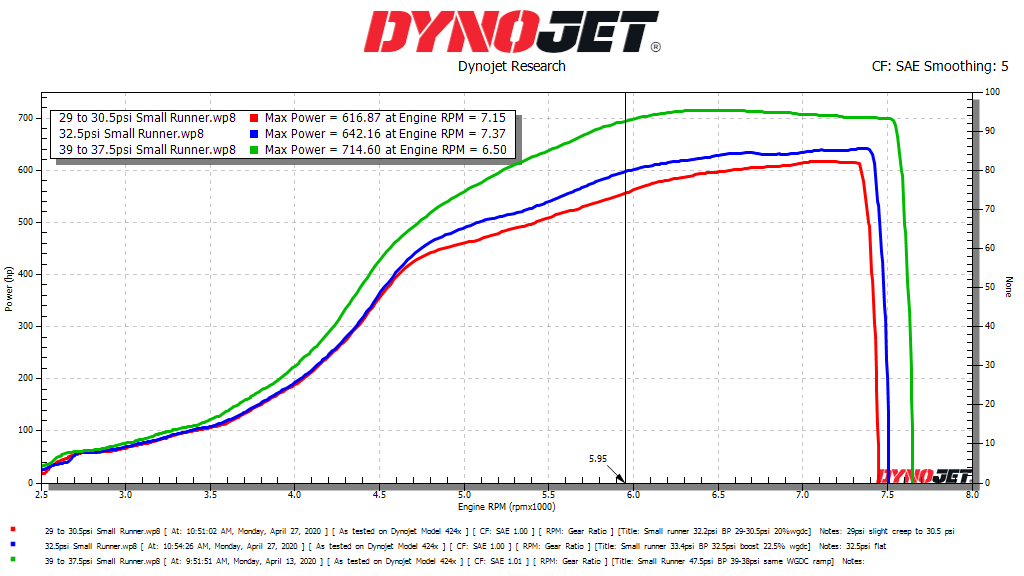

MF Small runner manifold overlaid at each boost level:

Red 29 to 30.5psi, blue 32.5psi, green 39 to 37.5psi

The green higher boost pull had the more aggressive boost ramp rate (the same as all of the large runner boost ramp rates) and the lower boost pulls had the softer boost ramp rate and illustrates how differently some of the small runner pulls came into boost. There may have been some other additional factors to possibly increase spool up in this particular 38psi run, such as the exhaust manifold possibly being at a higher initial temperature which could help spool, but either way this was the result when the boost ramp rate was the only known variable that changed.

The pulls all track nicely as boost increases, with the high boost pull leveling off sooner- likely starting to be dictated by the 62mm turbo getting closer to its limit.

Recap and Conclusions:

From John: (To be added)

During this test, the small runner manifold increased spool by 160-220rpm over the large runner manifold. This was also accompanied by a large increase in VE/fueling requirements, particularly during spool up, that resulted in more power/torque at the same boost level nearly everywhere with the smaller runner manifold. Torque was augmented from 40ft/lbs to as high as 125ft/lbs during spool up and as much as 42ft/lbs in peak torque numbers. Horsepower was augmented as much as 50whp at some points in the curve and ranged between 19-25 higher peak horsepower numbers.

Overall drive pressure/backpressure tended to be higher (less ideal) on the small runner manifold vs the large runner manifold. At 30psi, both were less than 1:1 boost vs drive pressure ratio which is fantastic (27psi and 29psi respectively), and at 32.5psi the large runner was at 1:1 and the small runner was just over 1:1. At 38psi, the large runner started to show a more favorable gap in drive pressure vs the small runner at only 43psi vs 47psi (both still fantastic for a 62mm 2.1L setup making 700whp).

Final Thoughts:

In this test, the small runner manifold spooled sooner, made more torque, and even made more peak power in every case. The 38psi runs in the 700whp range were the most telling, as we had expected the large runner manifold to overtake the small runner manifold in peak power numbers by at least a little, which did not happen. We were prepared for this test to make the small runner to look “bad” with this being an “on the fence” setup between large and small runners, but knew it would at least give us a better gauge for more informed suggestions to our clients and offer some insightful data that isn’t often shared.

We suspect that the power curves on this setup would have merged at around 8000rpm (they will merge either way as the turbo gets closer to its compressor limit, which looks to have happened, and plays a larger role in dictating the shape of the power curve at high rpm) and the large runner may have shown an advantage past that for holding power a little longer, but the small runner is more than capable of getting the most power from this 62mm 2.1L setup and ended up being almost hands down the best match. The only downside we saw was a few psi higher average drive pressure which did not affect the power in this case.

Our scale of factors for when large runner should be considered over small runner has certainly been nailed down more, with it looking like the advantage with larger runners won’t be seen until the 8k+ range and well into the 700whp power level, with some losses in the power curve likely everywhere else. Higher rpm based setups, larger turbos/higher power levels could easily change that, however. We already knew that our small runner manifolds would efficiently make 750whp, but we were a little surprised when they still made higher peak numbers vs large runner even at 700whp on this 62mm divided T4 setup.

That’s NOT to say large runner doesn’t rightfully have its place in higher power/higher rpm combinations and generate a great powerband, but it does back up the smaller runner size chosen for our stock replacements and the turbo options available to them.

It’s all about a well matched combination. We are happy to offer different runner sizes in order to create a setup that is the best match for you.

Details on Brandon’s Evo 9:

- Borg Warner S362SX-E with a 76mm turbine and .91A/R divided T4 turbine housing.

- Morrison Fabrications Large Runner Divided T4, Morrison Fabrications Small Runner Divided T4 (same placement and routing, primary size being the only difference). He kept the small runner 🙂

- Evo 9 cyl head w/ std Fererra valves, light port and polish, Kiggly high pressure street springs, Kiggly HLA.

- Kelford 280 cams (280/276).

- 2.1L destroker 4G64 block – 156mm Manley Turbo-Tuff rods, WSRD Diamond Spec Custom 10:1 pistons, OEM Evo 9 crank, WSRD oil modification.

- Link G4 with flex fuel and fail safes, Kiggly 12 tooth trigger wheel, JD Customs ignition coil setup.

- FIC 2150cc Injectors, Walbro 525/450 (Bullet Proof Billet double pumper), pump E85 (~e60 during this test).

- Skunk 2 intake manifold, stock throttle body, ETS 3” intercooler, 4″ WSRD Speed Density Intake.

- TiAl 50mm Q BOV, 2x TiAl MV-S 38mm external wastegates.